Leading Trends in Home Style Featuring Elegant and Practical Copper Products

Leading Trends in Home Style Featuring Elegant and Practical Copper Products

Blog Article

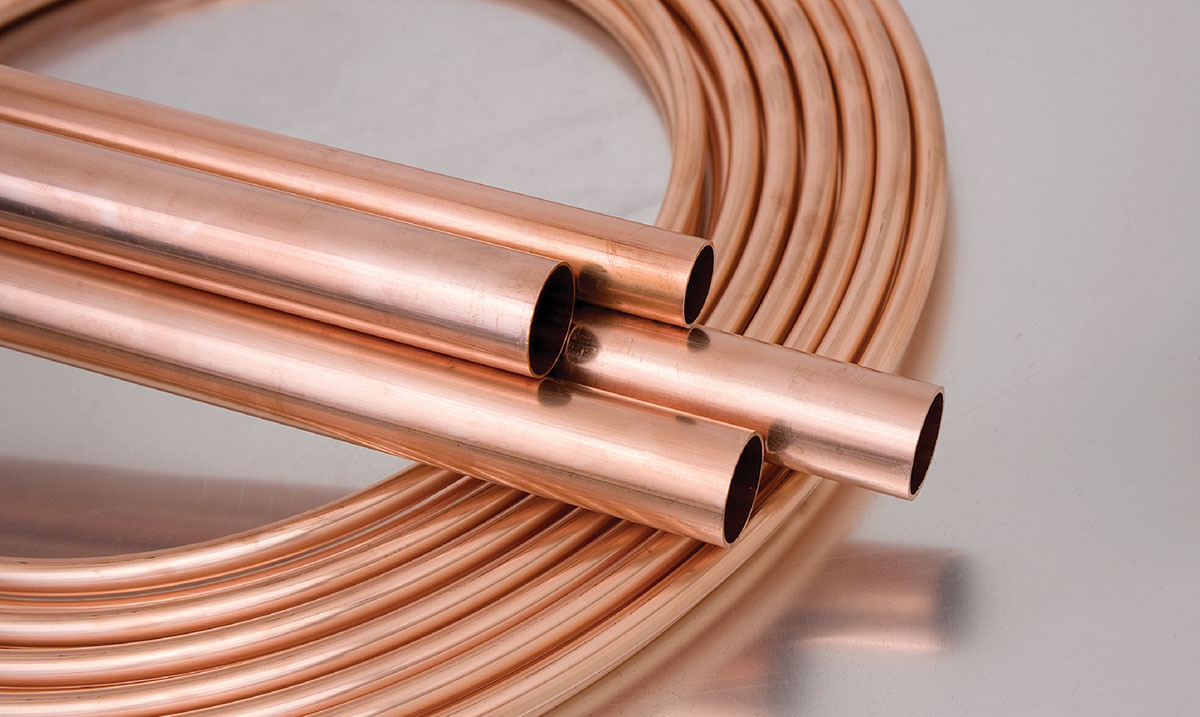

The Significance of High Quality in the Production of Copper Products

The relevance of quality in the manufacturing of copper items expands far beyond mere compliance; it is indispensable to maximizing efficiency throughout different industries. Top notch copper not just enhances conductivity however additionally assures sturdiness and dependability, which are critical in applications ranging from electronic devices to automotive systems. However, the ramifications of poor manufacturing methods can reverberate through expenses and security standards, inevitably affecting customer depend on. As we discover the diverse nature of top quality, the question arises: just how can manufacturers stabilize these difficulties to accomplish excellence?

Influence On Product Efficiency

The top quality of copper items plays a vital role in establishing their total performance in different applications. Top notch copper shows remarkable electric conductivity, thermal conductivity, and deterioration resistance, which are necessary qualities for sectors such as electronics, construction, and automotive.

Furthermore, the mechanical residential or commercial properties of copper, consisting of ductility and tensile toughness, significantly affect its efficiency in manufacturing processes. Copper items that meet stringent quality requirements can endure significant tension without warping, therefore boosting resilience and minimizing the chance of failing in demanding settings.

Furthermore, the surface coating of copper products effects their performance. A smooth, well-treated surface can stop oxidation and other types of degradation, ultimately prolonging the life of the element. In summary, the high quality of copper products directly impacts their performance, dependability, and durability throughout numerous fields, making it vital for makers to abide by extensive quality assurance procedures throughout the production procedure.

Price Implications mediocre

Buying top quality copper products is essential, as the expense implications mediocre can be considerable for end-users and makers alike. Low quality copper can bring about increased failure rates, causing pricey fixings and replacements. Manufacturers might deal with considerable downtime as faulty products demand recalls or remodel, disrupting production schedules and affecting general efficiency.

From an end-user viewpoint, the ramifications are similarly serious. Poor-quality copper can lead to ineffectiveness and enhanced operational costs, as tools may call for even more regular maintenance. Eventually, the initial financial savings gotten from selecting lower-quality copper items can be eclipsed by these long-term expenses, making the quest of top quality not just a matter of efficiency, yet a crucial economic consideration in the manufacturing market.

Security and Compliance Requirements

Ensuring security and conformity criteria in the manufacturing of copper items is critical to maintaining functional honesty and shielding both workers and customers. The manufacturing procedure should follow strict laws stated by organizations such as the Occupational Security and Health Management (OSHA) and the Epa (EPA) These policies describe crucial security methods, including appropriate handling of basic materials and waste management, guaranteeing a safe job environment.

Additionally, compliance with market standards such as ASTM International and ISO certification is crucial. These companies give guidelines that help suppliers apply finest techniques in high quality control and precaution. Regular audits and inspections ought to be carried out to ensure adherence to these standards, as non-compliance can bring about harmful problems and potential lawful ramifications.

Customer Trust and Satisfaction

Count on right here and fulfillment among customers play an essential role in the success of copper product suppliers (Copper Products). Top notch copper items not just satisfy rigid sector requirements however likewise satisfy consumer expectations, fostering commitment and repeat business. When consumers are positive in the top quality of the products they purchase, they are a lot more likely to create a long-lasting partnership with the supplier, which can lead to references and favorable word-of-mouth

To develop this count on, makers must focus on high quality control throughout the production procedure, making certain that each copper thing meets or surpasses requirements. Transparency in making methods, combined with commitment to customer solution, enhances the understanding of reliability. Moreover, timely delivery and responsiveness to customer questions significantly improve satisfaction levels.

Consumer feedback need to be proactively looked for and integrated right into item growth cycles to continually boost offerings. Involving consumers in dialogue regarding their choices and requirements cultivates a sense of partnership, further strengthening their rely on the manufacturer. Inevitably, a reputation for quality and customer-centric techniques identifies successful copper item makers in an affordable market, laying the groundwork for sustaining consumer partnerships.

Long-lasting Company Success

A producer's commitment to high quality is indispensable to accomplishing long-lasting company success in the competitive copper products market. Top notch items foster consumer commitment, guaranteeing repeat company and favorable recommendations that drive development. In a market where reliability and performance are paramount, business that prioritize top quality learn the facts here now over cost-cutting actions are more most Learn More Here likely to stick out.

Moreover, constant quality decreases the occurrence of issues and rework, resulting in reduced functional costs and boosted efficiency. This streamlined manufacturing procedure makes it possible for makers to allot resources successfully, enabling investments in technology and innovation. Businesses that adjust to market modifications and invest in top quality renovations are better positioned to meet progressing client needs.

Furthermore, keeping rigorous high quality criteria boosts a business's reputation, attracting possible partnerships and new customers. A durable online reputation for top quality can serve as a differentiator in congested markets, opening up doors to financially rewarding agreements and cooperations.

Eventually, an unfaltering commitment to high quality not just makes certain compliance with industry policies however also grows a lasting business version. By installing top quality right into every element of the production process, firms can safeguard their area as leaders in the copper products industry, leading the way for enduring success.

Conclusion

In final thought, the value of high quality in copper item manufacturing is vital. As industries progressively count on copper for crucial applications, keeping rigorous quality control is crucial to safeguard a competitive advantage and maintain a credible market presence.

The significance of top quality in the manufacturing of copper items expands much past simple conformity; it is important to optimizing performance throughout numerous markets. In recap, the top quality of copper items straight affects their functionality, reliability, and longevity across numerous fields, making it essential for makers to adhere to strenuous top quality control measures throughout the manufacturing procedure.

A producer's commitment to high quality is indispensable to attaining long-term organization success in the competitive copper items market.

Report this page